CC-Link IE network keeps power on track at Euston station

Accommodating the High Speed Two (HS2) railway line at London Euston station in the UK meant installing a new substation for the control of traction and electrical power to address the needs of the expanded facility. The technology used to deliver an exceptionally reliable and accessible high-speed network for this project was the open gigabit industrial Ethernet solution, CC-Link IE.

HS2 will use Euston station as its main terminus hub, with the number of seats out of the station during peak hours set to double. To support this increased capacity, the terminal is being enlarged to include 11 new 400-meter-long platforms for high-speed trains to and from London, the Midlands and north of England.

In order to meet the new electrification requirements of the expanded station, the telemetry system for the rail network’s electrical supply also needed to be upgraded.

When Sella Controls were asked to upgrade the substation control system, they proposed the use of TRACKLINK® remote terminal units (RTUs) developed in partnership with Mitsubishi Electric. This utilises a PLC to process signals from field devices, acting upon the information provided in a timely manner, as well as reporting data to SCADA systems in the control room.

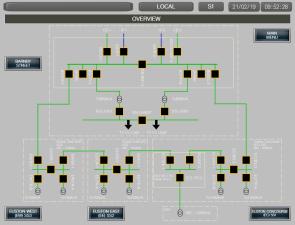

Since Euston station has always featured an extraordinarily large infrastructure, the control system uses an uncommon framework. Unlike smaller railway terminals, which only use a single RTU to address their needs, the London railhead’s electricity generation, transmission and distribution system is divided into multiple subsidiary parts. Known as substations, they are key for effective power distribution and control. The master RTU is used to link to remote I/O panels placed at each substation. Thanks to this setup, the main controller can complete auto reconfiguration procedures in the event of a power loss at the station.

Jay Sampat, Project Manager at Sella Controls, explains: “An RTU is typically a single panel deployment within a substation. However, depending on the structure of the railway terminal and its substations, some I/O can be remote. An example is Euston terminus, which comprises Euston Concourse, Euston East, Euston West and the new master location at Barnby Street Station. Whilst this type of setup is needed to successfully cover the entire infrastructure, it makes inter-substation communications particularly challenging.”

Fast-tracking traction power communications

To ensure reliable and fast inter-substation data transfer, a proven high-bandwidth open network technology was needed. This is why Mitsubishi Electric recommended to Sella Controls that it selects CC-Link IE.

This open industrial Ethernet technology offers gigabit bandwidth and uses a token passing method to provide real-time, deterministic communications. This minimises latency and jitter, facilitating the transmission of large volumes of data without congestion.

John Browett, General Manager at CLPA, comments: “The industry-leading functions of CC-Link IE were crucial to creating a high-speed telemetry system that can also address future data loads. The network that has been created is highly responsive and can be easily modified or upgraded as needed.”

Chris Elliott, Business Development Director for Rail at Sella Controls, adds: “The setup developed is unique, marking the first application of CC-Link IE for railway traction power control to deliver inter-substation connectivity. We look forward to setting up more cutting-edge control systems like this across the country soon.”

Full speed ahead

To ensure an exceptionally responsive control system, CC-Link IE was combined with Mitsubishi Electric’s iQ-R series modular PLC as the new building block of the RTU. Also, a GOT 2000 HMI was incorporated within the master RTU panel to maximise visibility and accessibility. David Bean, Solutions Group Manager at Mitsubishi Electric, says: “Our advanced automation components have been used for multiple Tracklink RTUs across the country and are delivering best-in-class performance. In this specific application, we were able to truly get the most out of our equipment to deliver interconnectivity between the main controller and the remote I/Os.”

Since the completion of the upgrade project at Euston station, the new telemetry solution has been key to ensuring a highly reliable traction power infrastructure within the terminal. John Browett concludes: “We are extremely proud to see our open network technology, CC-Link IE, being used to support this large-scale infrastructure project. As railways continue to advance and incorporate new technologies, we are well-positioned to deliver cutting-edge connectivity solutions to help realise reliable and accessible networks.”

About The CC-Link Partner Association (CLPA)

The CLPA is an international organisation founded in 2000 dedicated to the technical development and promotion of the CC-Link family of open automation networks. The CLPA's key technology is CC-Link IE TSN, the world's first open industrial Ethernet to combine gigabit bandwidth with Time Sensitive Networking (TSN), making it the leading solution for Industry 4.0 applications. Currently the CLPA has over 3,800 member companies worldwide, and more than 2,000 compatible products available from over 300 manufacturers. Over 26 million devices using CLPA technology are in use worldwide.

Editorial contact:

DMA Europa Ltd: Chiara Civardi

Tel: +44 (0)1562 751436 Fax: +44 (0)1562 748315

Web: www.dmaeuropa.com Email: chiara@dmaeuropa.com

Company contact:

CLPA-Europe: John Browett

Tel: +44 (0) 7768 338708 Fax: +49 (0) 2102 532 9740

Web: eu.cc-link.org Email: john.browett@eu.cc-link.org

The technology used to deliver an exceptionally reliable and accessible high-speed network for accommodating the High Speed Two (HS2) railway line at London Euston station was the open gigabit industrial Ethernet solution, CC-Link IE.

A remote terminal unit (RTU) is typically a single panel deployment within a substation. However, depending on the structure of the railway terminal and its substations, some I/O can be remote. An example is Euston terminus, which comprises Euston Concourse, Euston East, Euston West and the new master location at Barnby Street Station.

To ensure reliable and fast inter-substation data transfer, a proven high-bandwidth open network technology, such as CC-Link IE, was needed.

- CC-Link Partner Association (CLPA)

Members Site