The future of industrial communications lies in TSN

Innovative technologies are substantially reshaping industrial communications, enhancing their existing capabilities as well as providing new tools. Time-Sensitive Networking (TSN) is one of these and its essential role for industrial communications is becoming increasingly evident. This is why businesses should act now to implement TSN within their enterprises.

John Browett, General Manager at CLPA Europe, looks at why TSN is crucial to improve and futureproof industrial communications.

TSN is an innovative technology defined by IEEE 802.1 standards that resides at the Layer 2 (Data Link) of the Open System Interconnection (OSI) reference model for communications. It ultimately makes Ethernet deterministic by design, thus improving data transfer accuracy and reliability.

More precisely, two key pillars of TSN and its innovative deterministic capabilities are the IEEE 802.1AS - “Timing and Synchronisation for Time-Sensitive Applications” and IEEE 802.1Qbv - “Enhancements for Scheduled Traffic” sub-standards. These provide the foundation to offer deterministic performance.

A closer look at TSN standards

The first substandard, IEEE 802.1AS, is based originally on IEEE 1588 – "Standard for a Precision Clock Synchronisation Protocol for Networked Measurement and Control Systems”. It supports the synchronisation of all devices within a network with extreme accuracy by making sure that all network devices are operating according to a common time system. This time synchronisation is handled by a network clock master, also known as a ‘Grandmaster’. This sends time information in the format of Ethernet packets to each node and to the "Time-Aware System" within the network.

As a result, all devices operate according to the same clock, minimizing the likelihood of time drifts (jitter) that may lead to delays in data transfer. This is substantially different to what occurs on standard Ethernet networks, where each device has its own internal clock and the accumulation of time errors can lead to unwanted jitter.

IEEE 802.1Qbv leverages the synchronised environment created by IEEE 802.1AS to set up effective traffic scheduling systems. This sub-standard provides network switches with so-called time-aware shapers (TASs) to transport time critical data, such as motion and control information. A prioritisation of urgent and regular data is therefore possible with TASs, as periodic time windows (slots) are created based on Time Division Multiple Access (TDMA) models. During these intervals, only scheduled or reserved time- or mission-critical data is transmitted, without any interference.

In effect, since all TASs and network devices are synchronized, every node is aware of when priority data may be sent and processed. Consequently, sending and receiving times will be scheduled in the traffic definitions of the data packages.

Determinism supports data convergence

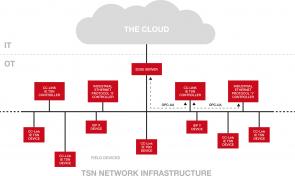

The TSN standards can avoid possible data loss by preventing network overload. In addition, traffic planning and the resulting determinism help companies to merge multiple types of traffic on one single network. For example, it is not only possible to combine I/O and motion control as well as safety communications without compromising performance. In fact, companies can also integrate other Ethernet traffic from cameras, barcode readers and printers, as well as other Ethernet protocols onto the same network.

Companies can also significantly reduce their capital expenditure (CAPEX) by simplifying the network architectures and making better use of their available network bandwidth. Simplified and clearly structured network architectures can reduce possible downtimes by streamlining the identification of errors and their elimination.

In addition, it is possible to use a more flexible infrastructure. With this, devices can easily be added or removed from the network as well as reconfigured while supporting different configuration philosophies. In addition, the transparency and convergence offered by TSN technology can help different parts of the company to access relevant data at different levels. This can have an extremely positive impact on a business' productivity.

Convergence is at the core of data-driven manufacturing

Enhanced process transparency and productivity can improve even further, as companies can utilize the capabilities of TSN to converge their information technology (IT) and operational technology (OT) worlds. Thus, digital transformation strategies provide data-driven insights that can utilised to optimise key operations.

The data transparency and convergence of TSN enables businesses to connect IT and OT to extract more data from industrial processes and analyse it by means of increasingly accurate and smart predictive models to gather meaningful knowledge on factory floor operations. This in-depth understanding can then be leveraged to improve performance, productivity, efficiency as well as end product quality.

Ultimately, TSN can support the creation of competitive and futureproof Connected Industries that support Industry 4.0 applications. Even more, the technology is well equipped to offer compatibility to new, potentially advantageous innovations, such as 5G. Therefore, companies should look at implementing TSN within their facilities now to get ready for the future of industrial communications while also addressing current needs.

A key solution that businesses should consider to adopt TSN now is CC-Link IE TSN, the first industrial Ethernet that features TSN functions in addition to gigabit bandwidth. This already offers a range of compatible devices and provides a comprehensive development ecosystem, which supports multiple industry-standard development options. By adopting CC-Link IE TSN, companies can rely on a proven technology to realise the full potential of TSN and its innovative capabilities with state-of-the-art products and applications that support Industry 4.0 frameworks.

To learn more about TSN and its role in the digital transformation of businesses, download CLPA’s latest whitepaper: https://eu.cc-link.org/en/campaign/2020/tsnwp

About The CC-Link Partner Association (CLPA)

The CLPA is an international organisation founded in 2000, now celebrating its 20th Anniversary. Over the last 20 years, the CLPA has been dedicated to the technical development and promotion of the CC-Link family of open automation networks. The CLPA's key technology is CC-Link IE TSN, the world's first open industrial Ethernet to combine gigabit bandwidth with Time Sensitive Networking (TSN), making it the leading solution for Industry 4.0 applications. Currently the CLPA has almost 3,800 member companies worldwide, and more than 2,000 compatible products available from over 340 manufacturers. Around 30 million devices using CLPA technology are in use worldwide.

Further Information:

Website: eu.cc-link.org

LinkedIn: https://www.linkedin.com/company/cc-link-partner-association-europe/

Twitter: twitter.com/cc_linknews

YouTube: youtube.com/user/CLPAEurope

Editorial contact:

DMA Europa Ltd. : Anne-Marie Howe

Tel: +44 (0)1562 751436 Fax: +44 (0)1562 748315

Web: www.dmaeuropa.com Email: anne-marie@dmaeuropa.com

Address: Europa Building, Arthur Drive, Hoo Farm Industrial Estate, Kidderminster, Worcestershire, DY11 7RA, UK

Reader contact:

CLPA-Europe : John Browett

Tel: +44 (0) 7768 338708 Fax: +49 (0) 2102 532 9740

Web: eu.cc-link.org Email: john.browett@eu.cc-link.org

Address: Postfach 10 12 17 40832 Ratingen Germany

- CC-Link Partner Association (CLPA)

Members Site